Gilans Ketan is a versatile abrasive material widely used in various industries for surface finishing, polishing, and deburring. This comprehensive guide delves into all aspects of Gilans Ketan, including its composition, manufacturing process, types, applications, advantages, disadvantages, maintenance, and safety precautions. Understanding these elements will help you make informed decisions about its use and ensure optimal results.

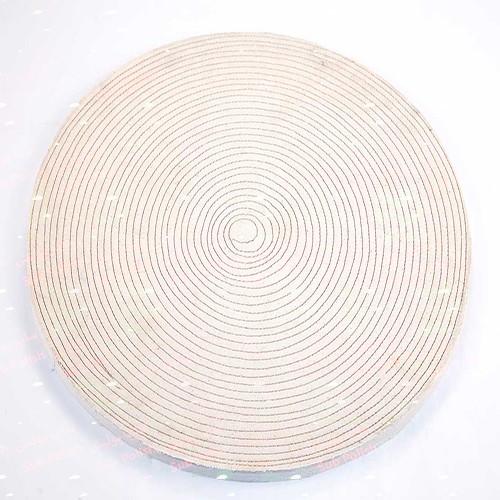

Gilans Ketan, often referred to simply as "Ketan," is a type of abrasive cloth or belt that is primarily used for surface finishing and polishing of various materials. It typically consists of abrasive grains bonded to a flexible backing material, such as cloth or paper. Gilans Ketan differs from traditional sandpaper in its composition and manufacturing, leading to superior performance in certain applications. It is especially favored in the metalworking industry for achieving a smooth and polished surface on metals like steel, aluminum, and brass.

The key components of Gilans Ketan include the abrasive grains, the bonding agent, and the backing material. Each of these elements plays a crucial role in determining the overall performance and durability of the abrasive.

Read more about سنباده رولی.

The manufacturing of Gilans Ketan involves a series of steps to ensure the proper bonding of abrasive grains to the backing material.

Gilans Ketan is available in various forms, each designed for specific applications. The main types include:

To know more about it, check out پرداخت کاری.

Gilans Ketan is used in a wide variety of applications across various industries. Some of the most common uses include:

Gilans Ketan offers several advantages over traditional abrasive materials, including:

While Gilans Ketan offers numerous advantages, it also has some drawbacks:

Proper maintenance and care can extend the lifespan of Gilans Ketan and ensure optimal performance.

When using Gilans Ketan, it is crucial to follow safety precautions to prevent injuries.

The manufacturing and disposal of Gilans Ketan can have environmental impacts.

Gilans Ketan can be compared with various alternative abrasive materials, each with its own strengths and weaknesses.

When purchasing Gilans Ketan, consider the following tips:

The abrasive industry is constantly evolving, with ongoing developments in materials and manufacturing processes. Future trends in Gilans Ketan include:

Q: What is the best grit size for polishing metal?

A: For polishing metal, start with a coarser grit (e.g., 120-180) to remove scratches and imperfections, then gradually move to finer grits (e.g., 400-600) for a smooth finish, and finally use a polishing compound for a high-gloss shine.

Q: How do I prevent Gilans Ketan from clogging?

A: Use a lubricant or coolant to help prevent clogging, and regularly clean the abrasive material with a brush or compressed air.

Q: Can I use Gilans Ketan on plastic?

A: Yes, but select fine grits and use low speeds to avoid melting or damaging the plastic.

For sandblasting services, visit the website aboutسنباده رولی read more in details.