Gilans Lea N نخي represents a specialized category of abrasive materials widely employed in various industrial applications for achieving superior surface finishing. This comprehensive guide aims to provide an in-depth understanding of its characteristics, applications, advantages, disadvantages, and best practices. This material is known for its flexibility and ability to conform to complex shapes, making it ideal for polishing and finishing intricate parts. The term "نخي" refers to the woven or fibrous structure of the abrasive material, which contributes to its unique properties and capabilities.

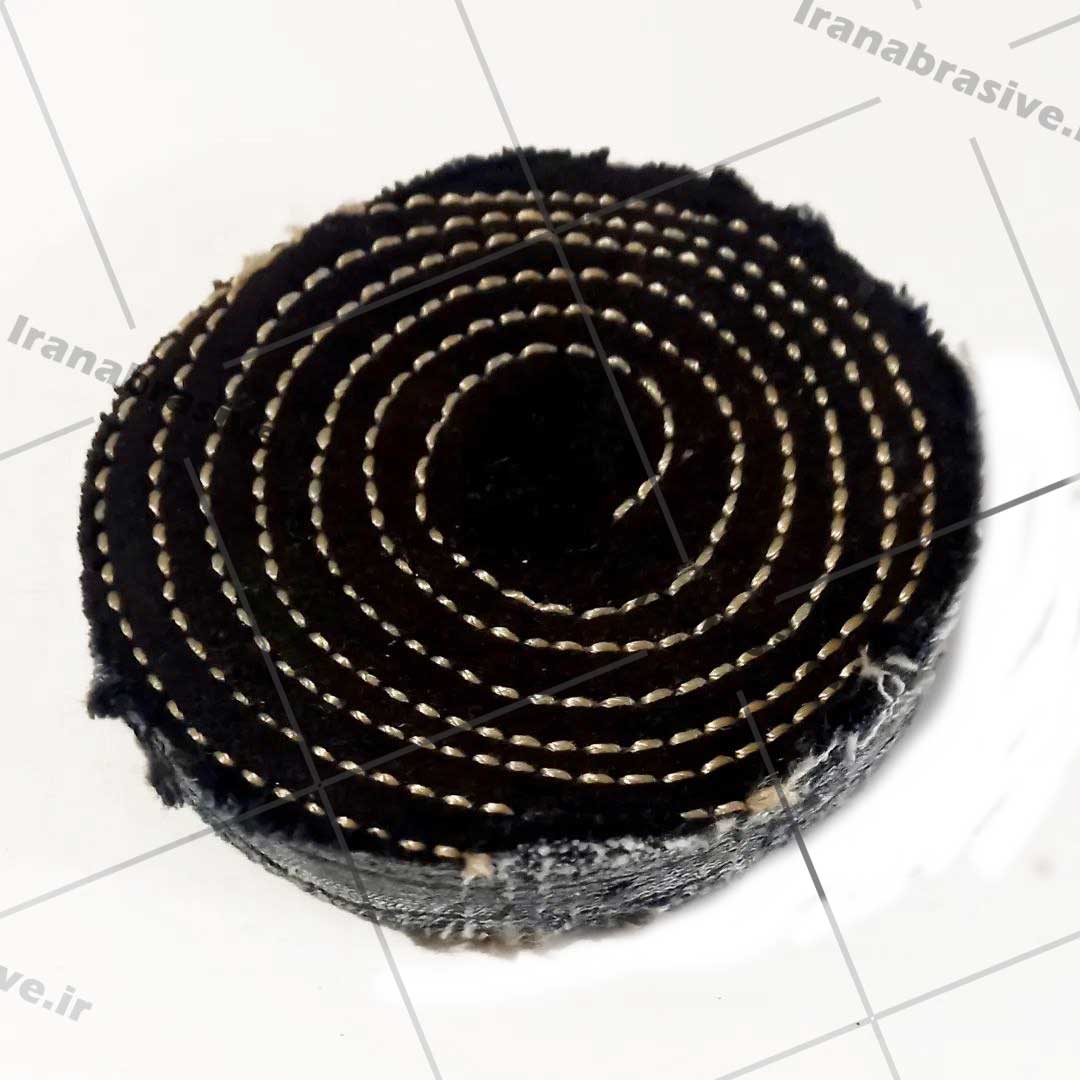

Gilans Lea N نخي is essentially a coated abrasive product where abrasive grains are bonded to a flexible, woven fabric backing. The "Lea" aspect likely indicates the type or grade of the abrasive grain used. The "نخي" (Nakhi) refers to the textile-like backing which provides both flexibility and strength. These abrasives are typically used in rotary tools and machines to achieve smooth, polished surfaces on a variety of materials. سنباده رولی are often used in similar finishing processes.

Gilans Lea N نخي finds applications across diverse industries due to its precision and adaptability:

Gilans Lea N نخي is available in various types, differentiated by grit size, backing material, and bonding agent. Understanding these variations is crucial for selecting the appropriate abrasive for a specific application.

The use of Gilans Lea N نخي offers several advantages over other abrasive methods:

Despite its advantages, Gilans Lea N نخي also has some limitations:

Proper usage is crucial to maximize the benefits and minimize the risks associated with Gilans Lea N نخي:

Safety should be a top priority when working with any abrasive material:

Understanding how Gilans Lea N نخي compares with other abrasive materials is important for making informed decisions:

Consider the following factors when selecting Gilans Lea N نخي پرداخت کاری :

To extend the life of Gilans Lea N نخي:

Provide real-world insights:

Technological leaps:

Gilans Lea N نخي سنباده رولی offer superior, versatile, and durable solutions for surface finishing. Proper precautions help you maximize the benefits while staying safe.