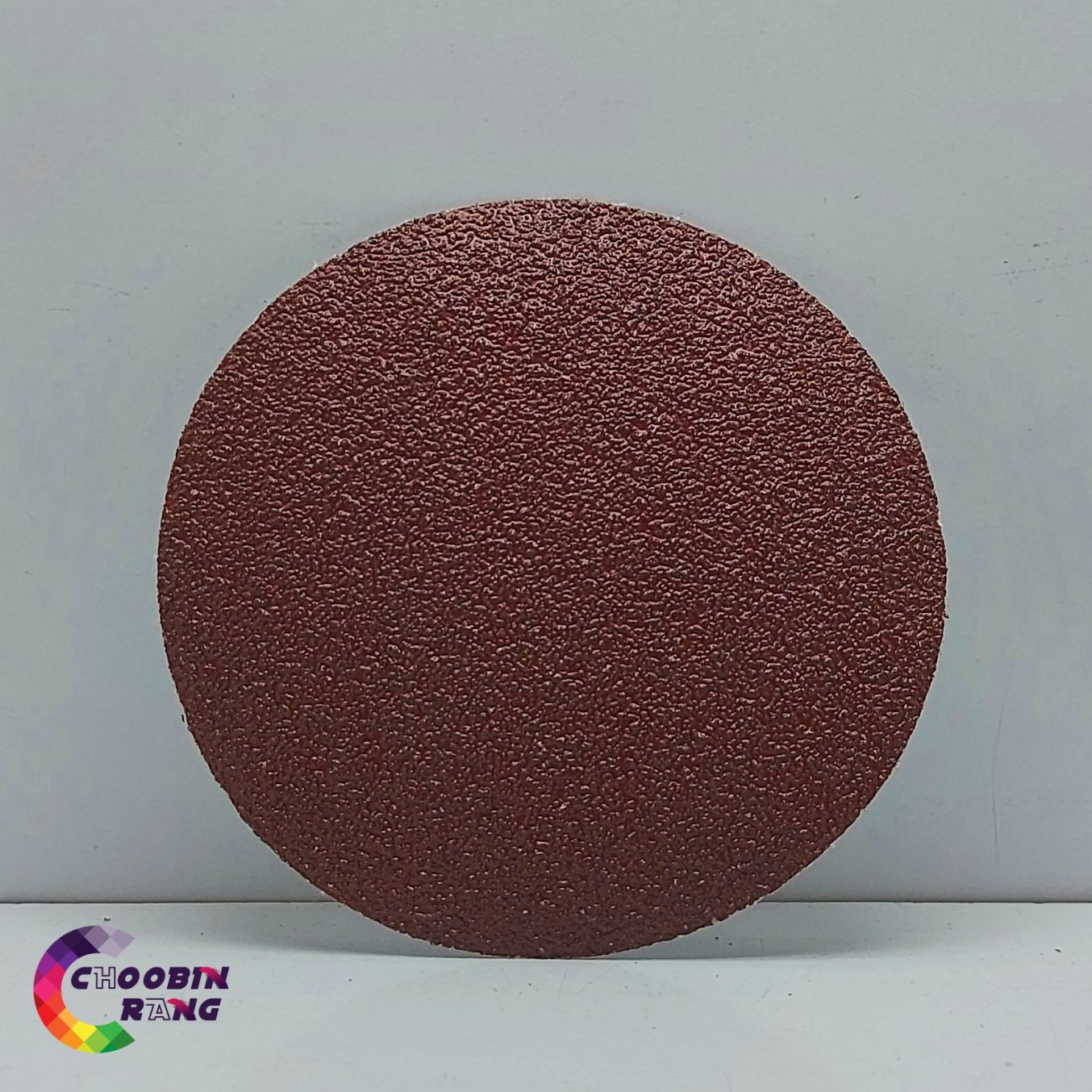

Hook and loop sanding discs, also known as Velcro sanding discs, are a type of abrasive disc used for sanding various materials, including wood, metal, plastic, and painted surfaces. They are characterized by their easy attachment and removal system, making them a popular choice for both professional tradespeople and DIY enthusiasts. This system consists of two layers: one layer with tiny hooks and another with loops, which interlock to hold the disc securely onto the sanding tool. This eliminates the need for adhesives or complex clamping mechanisms. They are available in a wide range of grits, sizes, and materials to suit different sanding applications.

A typical hook and loop sanding disc comprises several key components:

Hook and loop sanding discs offer several advantages over traditional adhesive-backed or clamped sanding discs:

Hook and loop sanding discs are widely used in various industries and applications, including:

Choosing the correct grit for a sanding disc is crucial for achieving the desired results. Here's a general guideline:

It's generally recommended to start with a coarser grit and gradually progress to finer grits to achieve the desired surface finish. Skipping grits can lead to uneven sanding and poor results.

Mounting and replacing hook and loop sanding discs is a straightforward process:

It's important to use a backing pad that is specifically designed for hook and loop sanding discs. Using an incompatible backing pad can damage the disc and reduce its performance.

When using hook and loop sanding discs, it's important to follow these safety precautions:

Ignoring safety precautions can lead to serious injuries.

Proper maintenance and care can extend the life of your hook and loop sanding discs:

Here are some common issues that may arise when using hook and loop sanding discs, and how to address them:

Hook and loop sanding discs are a versatile and efficient tool for a wide range of sanding applications. Their ease of use, reusability, and versatility make them a popular choice for both professional tradespeople and DIY enthusiasts. By following the guidelines outlined in this document, you can maximize the performance and lifespan of your hook and loop sanding discs and achieve excellent sanding results.

For more information on sanding tools and abrasives, visit Tehran Polish to learn more about سنباده رولی . You can also explore پولیش تهران for details on پرداخت کاری . And check out تهران پولیش for further insights on پرداخت کاری.