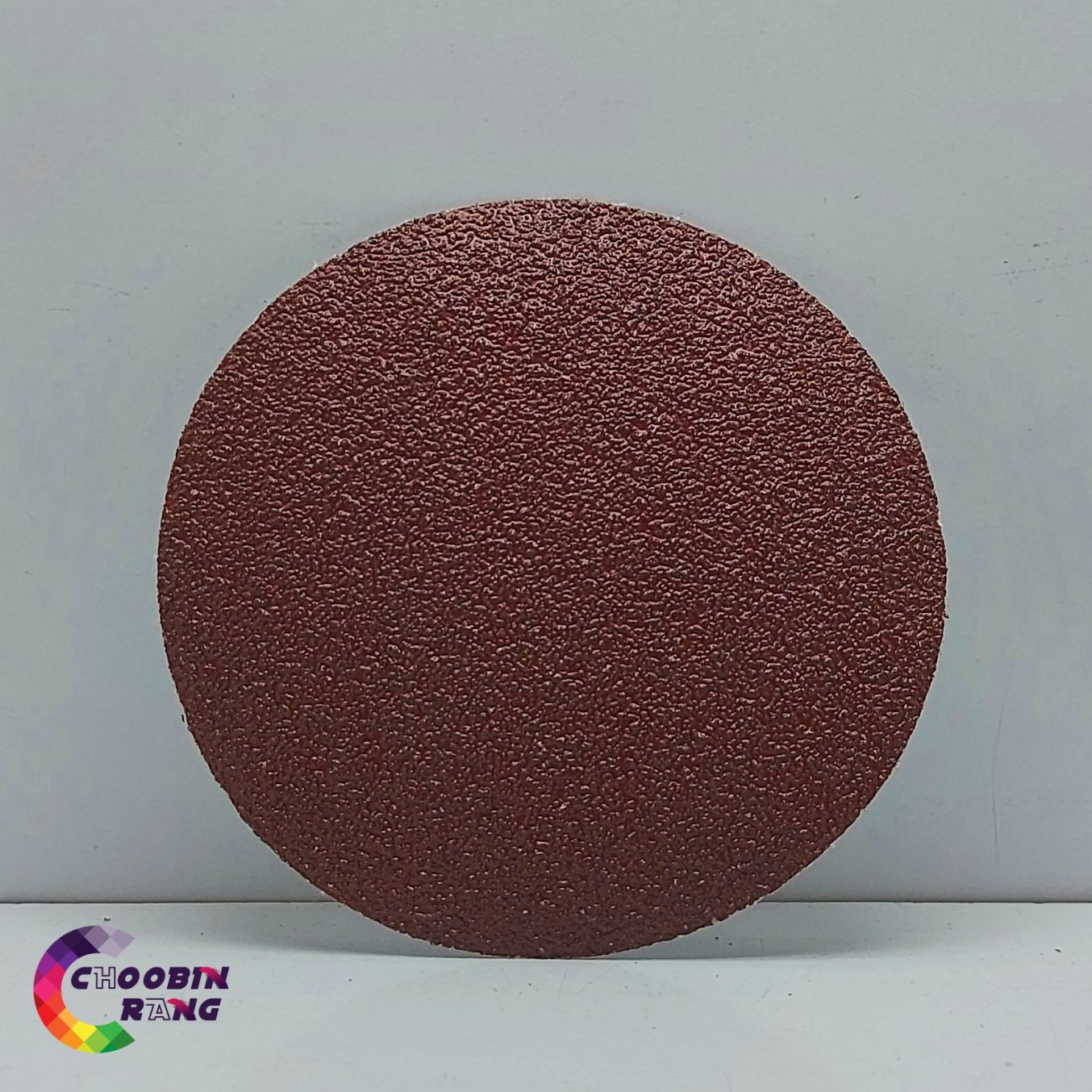

Hook and loop sanding discs, often called Velcro sanding discs, are a type of abrasive tool used for sanding and finishing various materials, including wood, metal, plastic, and composites. They are designed for use with power sanders that have a compatible hook and loop backing pad. The key feature of these discs is their easy attachment and removal, allowing for quick grit changes and increased efficiency in sanding processes. This convenience makes them a popular choice for both professional craftsmen and DIY enthusiasts.

This comprehensive guide will cover everything you need to know about hook and loop sanding discs, including their components, advantages, applications, grit selection, proper use, maintenance, and safety precautions. Whether you're an experienced woodworker or just starting out, this information will help you get the most out of your sanding projects. Learn more about related sanding products at تهران پولیش.

Understanding the components of hook and loop sanding discs is essential for choosing the right tool and using it effectively. The primary components include:

The quality of each component affects the disc's performance, lifespan, and suitability for specific tasks. For more information about abrasive materials, visit پولیش تهران.

Hook and loop sanding discs offer several advantages over traditional adhesive-backed or plain sandpaper. These advantages include:

These benefits make hook and loop sanding discs a superior choice for many sanding applications. For tips on improving your sanding process, see تهران پولیش.

Hook and loop sanding discs are versatile tools used in a wide range of applications. Some common applications include:

The versatility of hook and loop sanding discs makes them an indispensable tool for professionals and hobbyists alike. Discover more applications for your projects at پولیش تهران.

Choosing the right grit for your sanding disc is crucial for achieving the desired results. Grit refers to the size of the abrasive particles on the disc, with lower numbers indicating coarser grits and higher numbers indicating finer grits. Here is a general guide:

It's generally recommended to start with a coarser grit to remove imperfections and then gradually move to finer grits to achieve a smooth finish. Skipping grits can result in uneven sanding and a poor final product. Read more about grit options at تهران پولیش.

Hook and loop sanding discs are suitable for a wide range of materials, including:

Selecting the appropriate abrasive material and grit for the specific material you are sanding is essential for achieving the best results. Softer materials may require finer grits to avoid scratching, while harder materials may require coarser grits for effective material removal. Explore suitable materials at پولیش تهران.

Hook and loop sanding discs are designed to be compatible with a variety of power sanders, including:

When selecting sanding discs, ensure that the disc size matches the backing pad size of your sander. Using the wrong size disc can damage the sander and lead to uneven sanding. Verify compatibility with your tools at تهران پولیش.

To achieve optimal results when using hook and loop sanding discs, follow these tips and techniques:

Proper technique can significantly extend the life of your sanding discs and improve the quality of your work. Read more about sanding techniques at پولیش تهران.

Proper maintenance and care can extend the life of your hook and loop sanding discs and backing pads. Follow these guidelines:

By following these maintenance tips, you can ensure that your sanding tools remain in good condition and perform optimally. Find cleaning supplies and maintenance tips at تهران پولیش.

Safety should always be a top priority when using power tools. Here are some important safety precautions to follow when using hook and loop sanding discs:

Following these safety precautions will help prevent accidents and injuries. Review safety guidelines at پولیش تهران.

Even with proper use and maintenance, you may encounter some common issues when using hook and loop sanding discs. Here are some troubleshooting tips:

By addressing these common issues, you can improve your sanding results and extend the life of your sanding tools. Find solutions and support at تهران پولیش.

Proper storage and handling can prevent damage and prolong the lifespan of hook and loop sanding discs. Here are some best practices:

Following these storage and handling practices will help keep your sanding discs in good condition and ready for use. Explore storage solutions at پولیش تهران.

There are several reputable brands that manufacture high-quality hook and loop sanding discs. Some of the top brands include:

When choosing sanding discs, consider the brand's reputation, the quality of the abrasive material, and the compatibility with your sanding tools. Compare brands and read reviews at تهران پولیش.

The field of sanding technology is continually evolving, with ongoing research and development focused on improving efficiency, performance, and user experience. Some emerging trends include:

Staying informed about these trends will help you take advantage of the latest advancements in sanding technology and improve your sanding processes. Stay updated on the latest trends at پولیش تهران.