Maintenance and Care

Preventive Maintenance Schedule

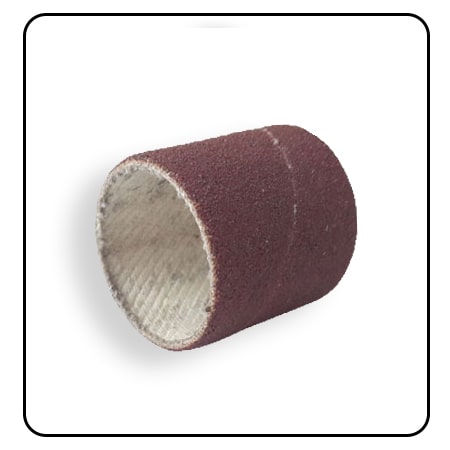

Regular maintenance ensures optimal loop sandpaper performance, extends belt life, and maintains consistent surface quality. Establishing a systematic maintenance routine is essential for professional operations.

| Maintenance Task | Daily | Weekly | Monthly | Quarterly |

|---|---|---|---|---|

| Belt Inspection |