Sandpaper, also known as abrasive paper, is a fundamental tool in numerous industries and DIY projects. Its primary purpose is to smooth surfaces, remove material, and prepare surfaces for finishing by abrasion. It consists of an abrasive material bonded to a backing material.

The effectiveness of sandpaper largely depends on the type of abrasive grain used. Here are some common types:

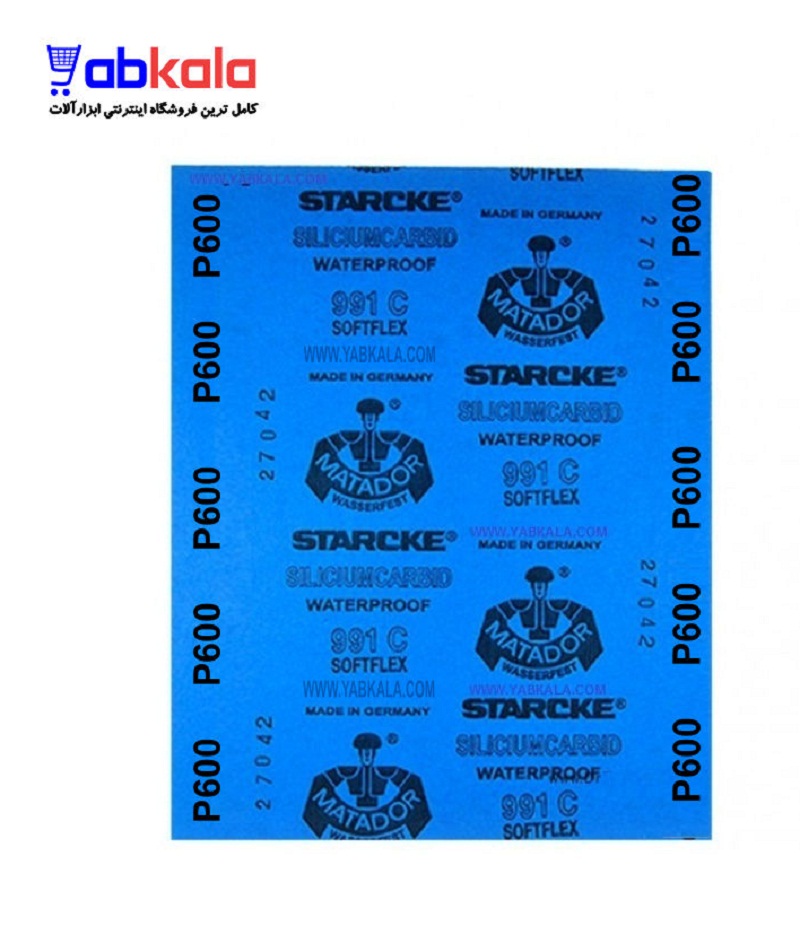

Grit size refers to the particle size of the abrasive material. The lower the grit number, the coarser the sandpaper and the more material it removes. Conversely, higher grit numbers indicate finer sandpaper, used for smoothing and finishing.

Common grit ranges include:

Choosing the correct grit sequence is crucial for achieving the desired finish. Start with a coarser grit to remove imperfections and gradually move to finer grits to smooth the surface.

For more information on abrasive processes, consider exploring سنباده رولی تهران پولیش or پرداخت کاری پولیش تهران

The backing material provides support for the abrasive grains and influences the sandpaper's flexibility and durability. Common backing materials include:

Coatings applied to sandpaper can affect its performance and lifespan.

Sandpaper comes in various formats to suit different applications:

Sandpaper is an essential tool in woodworking for:

Generally, a sanding sequence from coarse to fine grit is used to achieve a smooth, paintable wood surface.

In metalworking, sandpaper (often referred to as abrasive paper) is used for:

Silicon carbide and ceramic aluminum oxide sandpapers are commonly used for metalworking applications, often with a lubricant to reduce heat and prevent clogging. It's always imperative to wear proper safety gear when doing this.

For more information on abrasive processes, consider exploring سنباده رولی تهران پولیش or پرداخت کاری پولیش تهران

Sandpaper plays a critical role in automotive refinishing for:

Wet sanding involves using water as a lubricant to reduce friction and prevent clogging. It's used after painting clear coat to remove imperfections, such as orange peel.

Sandpaper is also used on various other materials:

Effective sanding techniques can significantly improve the results:

For more information on abrasive processes, consider exploring سنباده رولی تهران پولیش or پرداخت کاری پولیش تهران

Safety is paramount when sanding:

Proper storage and maintenance can extend the life of your sandpaper:

Common sanding problems and solutions:

The sandpaper industry is constantly evolving, with new developments focused on:

Choosing sandpaper options that minimize environmental impact is becoming increasingly important:

For more information on abrasive processes, consider exploring سنباده رولی تهران پولیش or پرداخت کاری پولیش تهران