Sandpaper, also known as abrasive paper, is a fundamental tool in woodworking, metalworking, automotive repair, and various other industries. It is used to smooth surfaces, remove material, prepare surfaces for finishing, and even create decorative effects. Its effectiveness lies in its simplicity – a flexible backing coated with abrasive particles. Understanding the nuances of sandpaper, from its grit to its material composition, is crucial for achieving professional-quality results.

Different projects need different kinds of sandpaper. For example, coarse sandpaper is great for quickly removing a lot of material. In contrast, fine sandpaper gives a really smooth final surface. Knowing which sandpaper is right for the task at hand drastically improves efficiency and the overall finish. Want to learn more about abrasive tools? Check out تهران پولیش.

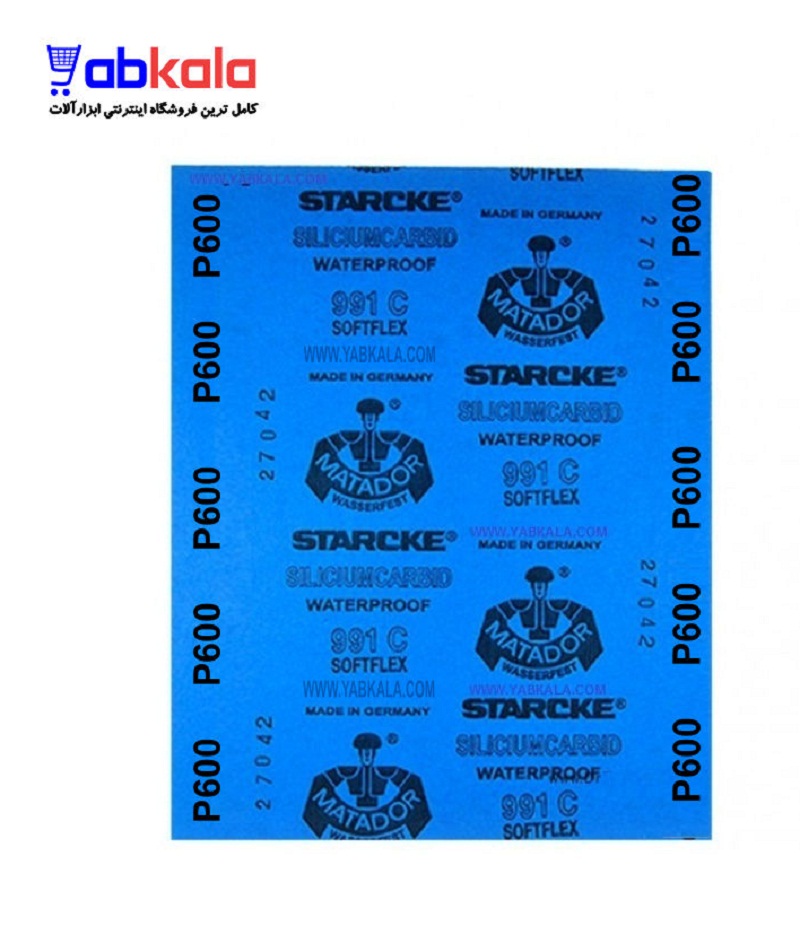

The term "grit" refers to the particle size of the abrasive material on the sandpaper. It's indicated by a number on the back of the sandpaper sheet. The lower the number, the coarser the grit, meaning the larger the abrasive particles and the more material the sandpaper removes. Conversely, a higher number indicates a finer grit, ideal for smoothing and polishing. It’s essential to start with the correct grit for the job. Too coarse, and you risk gouging the surface; too fine, and you'll waste time and effort.

Grit ranges typically fall into the following categories:

To find more information about the abrasive paper and sanding related topics, you might find interesting details on پولیش تهران.

Sandpaper comes in various types, each designed for specific applications and materials:

Choosing the right type of sandpaper depends heavily on the material you're working with and the desired outcome. For instance, silicon carbide sandpaper is preferred for wet sanding car bodies because of its sharp cutting edges. To learn more about the latest trends and technologies in abrasive tools, explore تهران پولیش.

Sandpaper consists of three primary components: the backing, the abrasive, and the bonding agent.

The quality of these materials directly impacts the sandpaper's performance and lifespan. High-quality sandpaper typically uses durable backing and bonding materials to ensure consistent performance and prevent premature wear. More details about the construction and materials used in various abrasive products can be found on پولیش تهران.

Sandpaper is available in various forms to suit different tools and applications:

The choice of form depends on the tool being used and the nature of the sanding task. For example, sanding rolls are the perfect choice of سنباده رولی.

Effective sanding requires proper technique to achieve the desired results without damaging the surface. Here are some important considerations:

Mastering these techniques can significantly improve the quality of your sanding and the overall finish of your projects. You can learn more about refining your techniques and achieving professional results with guidance from پولیش تهران.

Sanding can generate dust and particles that can be harmful if inhaled or come into contact with the eyes. It's crucial to take the following safety precautions:

Prioritizing safety ensures a clean and healthy working environment. You can find more information on safety practices and protective gear for sanding via تهران پولیش.

Maximize the lifespan of your sandpaper by following these tips:

These practices ensure that your sandpaper remains effective for longer, saving you money and reducing waste. Explore پولیش تهران for more cost-saving tips and effective maintenance strategies for your tools.

Even with proper technique, you might encounter issues during sanding. Here's a guide to troubleshooting common problems:

Addressing these issues promptly prevents them from escalating and compromising your finish. For more problem-solving strategies and expert tips on achieving optimal outcomes in surface preparation, visit تهران پولیش.

Sandpaper is used in a wide variety of applications across diverse industries:

Sandpaper is an extremely important tool for پرداخت کاری. Understanding its diverse applications helps you leverage its versatility in various projects.

While sandpaper might seem like a simple tool, it's important to consider its environmental impact and proper disposal methods.

By adopting these practices, you can minimize the environmental footprint associated with sandpaper use. Look into environmentally friendly tools at تهران پولیش to find options that align with sustainability goals.